The electric control system

The electric control system is consisted of a (set of) computer plus PLC mode to realize effective control. The system performs sampling, calculating, comparing, processing of the external signals and the control of input/output command, which realizes the control over the external executors, manages starting/stopping of mechanical-electrical doors of peripheral hoppers, and therefore performs effective control of automatic production. In case an agitator is out of order, the other agitator may be started automatically to guarantee the unceasing operation of the machinery without any trouble.

Electronic components are selected from such manufacturers as Schneider, Siemens, LG, Omron, Meanwell, Weidmuller, Toledo and so on, which guarantees effectively the stability of electric control system.

Main Features and Functions of the System

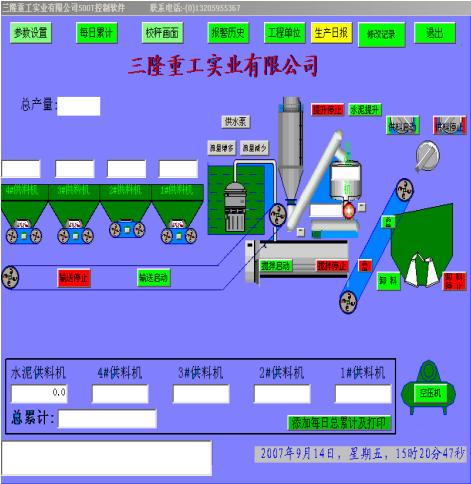

It is equipped with centralized monitoring and VGA high-definition colorized display. Hints on Chinese menu are legible and concise which are easy to understand and operate. Industrial PC is adopted as host computer which boast strong anti-jamming and reliable work. Parameters are able to be entered and modified online. Documents can be printed. It is equipped with power cut protection functions, which means that the data won't be lost when power is off or the computer is shut down. The computer will save all data eternally and it is unnecessary to enter the data again when you start the computer again.

The newest design concept of the program of control system

The control system adopts Windows as the operation platform, takes the production control as its key task, and adopts such control manner as "industrial control computer + industrial programmable controller "or" industrial control computer + weighing instrument + control board". It is an automatic control system of high stability, high real time capability and high intelligence. The control program of the upper computer of the industrial control integrates the most advanced concept of simulation neural network model in industrial control at home and abroad, i.e. the program has simulation function, real time state control, self-execution and self-study on real time information feedback on the working state of the equipment. The output signal state of the industrial programmable controller is decided by the set functions of the control program of the upper computer, to control the opening and closing of each hopper gate and to control the start-up and shut off of the motor, to realize auto control production.

The newest design concept of the program of control system

1.The newest control technique for compensating overshoot: intense vibration will occur when the loader feeds silo on the field or when the cement arch is broken by compressed air, which causes the instability of measurement of impact. By this function, the control of impact on the field may be corrected effectively and intelligently to guarantee stable and accurate weighing.

2.The Function of intelligent control: based on the proportioning determined by users in advance, the speed will be regulated by frequency conversion to assist production in the manner of proportional adjustment to reach the expected production capacity.

3.The function of intelligent timing control: any timing control can be set to meet the needs in production

4.The function of intelligent information alarm: real time indications on the running state of the system are given and false operations of the user are explained The frequency converter may reflect the current frequency range and its utilization at any time, and possesses such function as automatic fault alarm..

5.The function of the flow memory control: the stability and intelligence of the system control can be realized through formed flow memory control, so as to reach the philosophy of actual auto control.

6.The function of the operation log: it may register effectively each operation procedure after operators have logged in the control system, which performs effectively the operation management in the manner of black box.

Production report forms for all customers/recipes.

Transportation report forms for all vehicles.

Daily, monthly and annual report forms for material consumptions.

Daily, monthly and annual report forms for production capacity.

Daily, monthly and annual report forms for transportation volume.

Friendly man-machine interface, characterized by high efficiency and real time, may present the production status on the field to us in the manner of cartoon or data, judge and analyze the operation condition on the field intelligently, and implement strictly the humanistic automatic control of production.