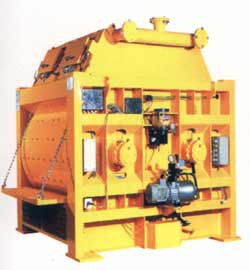

The concrete mixer, a forced type mixer developed singly by our company in the end of 1990's, leads the whole world in respect to the technological advance and has formed 4 major series consisted of 13 kinds through the unceasing innovation for over ten years.

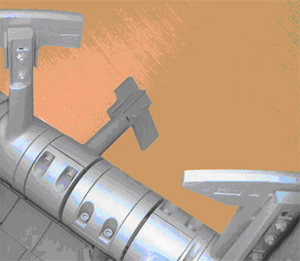

The unique shaft-end sealing techniques: the shaft-end usesspecial material to make up antifriction sealing circle, it is to strengthen shaft-end sealing reliability and prevent slurry leakage The workloadfordaily maintenance is lessened and the cycle of overhauling is prolonged.

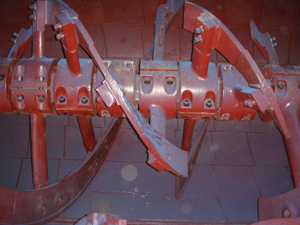

Mixing arms' streamline design: the layout of mixing arms has strong spiral turning ability to guarantee high efficient of mixing.

Mixing arms' streamline design: the layout of mixing arms has strong spiral turning ability to guarantee high efficient of mixing.

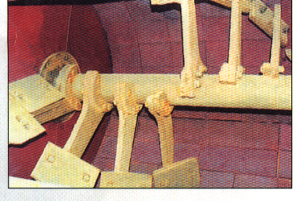

Rotating and sealing parts can be greased automatically: the new-type of greasing system is designed by our company .The mixing shaft-end and sealing parts can be greased automatically (or manually) to guarantee reliable mixing, prevent damaging working mechanism caused by concrete adhesion or solidify.

Mixing shaft's bearing and shaft-end sealing are separated: this design avoids slurry leakage when the sealing devices break down or damage bearing. Meanwhile, it is convenient for shaft-end sealing or bearing maintenance and replacement.

The concrete mixer, a forced type mixer developed singly by our company in the end of 1990's, leads the whole world in respect to the technological advance and has formed 4 major series consisted of 13 kinds through the unceasing innovation for over ten years.

The unique shaft-end sealing techniques: the shaft-end usesspecial material to make up antifriction sealing circle, it is to strengthen shaft-end sealing reliability and prevent slurry leakage The workloadfordaily maintenance is lessened and the cycle of overhauling is prolonged.

Mixing arms' streamline design: the layout of mixing arms has strong spiral turning ability to guarantee high efficient of mixing.

Mixing arms' streamline design: the layout of mixing arms has strong spiral turning ability to guarantee high efficient of mixing.

Rotating and sealing parts can be greased automatically: the new-type of greasing system is designed by our company .The mixing shaft-end and sealing parts can be greased automatically (or manually) to guarantee reliable mixing, prevent damaging working mechanism caused by concrete adhesion or solidify.

Mixing shaft's bearing and shaft-end sealing are separated: this design avoids slurry leakage when the sealing devices break down or damage bearing. Meanwhile, it is convenient for shaft-end sealing or bearing maintenance and replacement

|

|

| JSL Series Double Helical Ribbon Mixing Building is the latest model of our company. Its continuous mixing paddles can provide amazing mixing capability, not only shortening the mixing time, but also producing high quality concrete. The mixing performance of the product is high beyond the national standard. |

|

|

|

|

| JS Series Standard Double Horizontal Shaft Forced Mixer is the fruit of advanced mixing technology introduced from Europe in the beginning of the 20th century. Its mixing performance achieves the European standards and surpasses the national standard. |

|

|

|

|

| JSJ Series Simplified Double Horizontal Shaft Forced Mixer is the earliest product that our company developed at the end of the 1990s, of which the mixing performance meets the national standard. |

|

|

|

|

| JD500 Single Horizontal Shaft Mixer is the first single horizontal shaft mixer designed by our company at the end of the 1990s in China. Its high energy efficiency, simplicity, stability, reliability and side-output can effectively simplify the structure of the mixing plant. |

Main technical specifications

| JSL Series Double Helical Ribbon Mixing Building |

| Model |

Charging Volume(L) |

Discharging Volume(L) |

Mixing Electric motor(kW) |

Lubrication Type |

Discharging Type |

Weight(kg) |

| JSL1500 |

2200 |

1500 |

2x30 |

Automatic |

Hydraulic drive |

7000 |

| JSL2000 |

3200 |

2000 |

2x37 |

Automatic |

Hydraulic drive |

9000 |

| JSL3000 |

4500 |

3000 |

2x55 |

Automatic |

Hydraulic drive |

11000 |

| JSL4000 |

6000 |

4000 |

2x75 |

Automatic |

Hydraulic drive |

13000 |

|

| JS Series Standard Double Horizontal Shaft Forced Mixer |

| Model |

Charging Volume(L) |

Discharging Volume(L) |

Mixing Electric motor(kW) |

Lubrication

Type |

Discharging Type |

Weight(kg) |

| JS1500 |

2200 |

1500 |

2x30 |

Automatic |

Hydraulic drive |

6500 |

| JS2000 |

3200 |

2000 |

2x37 |

Automatic |

Hydraulic drive |

7500 |

| JS3000 |

4500 |

3000 |

2x55 |

Automatic |

Hydraulic drive |

9200 |

| JS4000 |

6000 |

4000 |

2x75 |

Automatic |

Hydraulic drive |

11200 |

|

| JSJ Series Simplified Double Horizontal Shaft Forced Mixer |

| Model |

Charging Volume(L) |

Discharging Volume(L) |

Mixing Electric motor(kW) |

Lubrication

Type |

Discharging Type |

Weight(kg) |

| JSJ1000 |

1600 |

1000 |

2x18.5 |

Automatic /Manual |

Hydraulic drive /pneamuic operated |

4500 |

| JSJ1500 |

2200 |

1500 |

2x30 |

Automatic /Manual |

Hydraulic drive /pneamuic operated |

6000 |

| JSJ2000 |

3500 |

2000 |

2x37 |

Automatic /Manual |

Hydraulic drive /pneamuic operated |

7500 |

| JSJ3000 |

4500 |

3000 |

2x55 |

Automatic /Manual |

Hydraulic drive /pneamuic operated |

9500 |

|

| JD500 Single Horizontal Shaft Mixer |

| Model |

Charging Volume(L) |

Discharging Volume(L) |

Mixing Electric motor(kW) |

Lubrication

Type |

Discharging Type |

Weight(kg) |

| JD500 |

800 |

500 |

18.5 |

Automatic /Manual |

Hydraulic drive |

3000 |

| JD750 |

1200 |

750 |

30 |

Automatic /Manual |

Hydraulic driv |

4000 |